top of page

_edited_edited_.png)

Los Angeles County • Orange County • Riverside County • San Diego County

Lic. 365352

PREVENTATIVE MAINTENANCE

Energy Efficient Equipment

Since its founding, Eastside Service has been one of the most trusted names in the industry. Hire us for this service and learn how we cater to the needs of each client, ensuring the results you need and deserve.

A preventative maintenance program is a must for a facility if they want to be able to run at 100%. Restaurants house multiple pieces of cooling equipment ranging from their reach in coolers to ice machines to their air conditioners. Have any of those units go down and it will hinder sales and make it hard for the team to work effectively let alone trying to keep your customers there if the AC is out. While you can’t predict or prevent every system failure you can minimize the amount of down time by having a program in place.

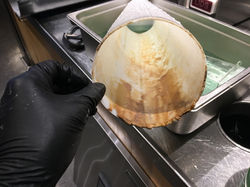

One of the tasks that is included in a Pm program is having your condenser coils chemically cleaned. This specific action could save you thousands of dollars down the line in preventing compressor burnouts or clogged metering devices; both of which would require opening up the system for replacement. This particular piece of the system is responsible for rejecting heat from the space you are conditioning, if the coil is dirty or clogged system pressure and heat rise dramatically. You can see how it would be difficult for air to pass thru the coil in these before and after pics.

|  |

|---|

If this system was left in a dirty state, the compressor could overheat and also break down the oil to a point where it clogs a capillary tube. After that, both the compressor and cap tube would need to be replaced. Leading up to the final symptom, you’ll notice gradual changes in the temperature of the food as it’s difficult for the system to remove the heat during a lunch or dinner rush. If you know for a fact that there isn’t a program in place, it’s recommended to reach out to your service provider as soon as possible.

Another aspect of a Pm program is ensuring drain lines and drain pans are clear of debris. As the business is open and serving customers, food drops and sometimes lands in the drain pans. This food is sometimes heavy and will sit there for weeks or months building up but at the same time breaking down. These food particles will start to flow down the drain line and plug it up. This could lead to water overflowing into the fixture and also cause a coil to ice over. Below is an example of an area that we stumbled across when we took over a new restaurant.

|  |

|---|

The first Pm that’s performed at a new location is typically the longest. What’s found at these sites are a number of days of heavy build up on the fan guards and fan blades. Like with all air cooled systems, if the airflow is not correct, the potential of motor failure is high. One needs to remember that the air passing over these fan guards is also passing over food; any customer would expect a clean kitchen with clean equipment.

|  |

|---|

The Walk-in Cooler is one of the most important stations in the restaurant, yet when left neglected, it can also breed some heavy build up. It’s essential that this locations equipment be maintained on a regular basis.

|  |

|---|

In other sections of this site, you’ll find additional pictures on specific equipment. The purpose is to help restaurant owners and managers feel comfortable with their equipment and to show them the signs to look for when they suspect that a PM is needed or even what to check for after a PM has been completed. Some signs should be obvious when to take action.

Others are hidden behind panels that are of an unknown nature. The only ones who would typically look are a service provider or a manager when the system is down. Customers be aware.

|  |  |  |

|---|---|---|---|

|

bottom of page